"WHAT PROBLEM AM I TRYING TO SOLVE?" | Solving Problems Real Time! | 1.10

LISTEN TO LEARN | SOLVING PROBLEMS REAL TIME! | LBFF 1.10

Concluding our series on the Imai Process of Continuous Improvement, where we’ve gone into a little more detail about some of the Lean tools in our toolbox, is REAL TIME PROBLEM RESOLUTION (RTPR) or the fifth stage of our Continuous Improvement Journey!

“Why do I need to have RTPR? What problems are we trying to solve?” Real Time Problem Resolution (RTPR) is the process that utilizes the Lean tools like Visual Controls and Standard Work…Listen to find out how!

WATCH TO TRY | "Solving Problems Real Time!" with Jeff Raley | LBTT 1.10

what is REAL TIME PROBLEM RESOLUTION (RTPR)? Is this a tool or a process? Watch our latest interview with Jeff Raley, a Retired aerospace professional and consultant. Jeff discusses with us the intent behind Real Time Problem Resolution; not only in his professional life, but also in his personal life. He explains the benefits of RTPR and how this process has made his teams successful in their commitment to continuous improvement…Watch to Learn More!

READ TO APPLY | Solving Problems Real Time! | LBCC 1.10

The Imai Process of Continuous Improvement is my favorite methodology for implementing lean. There are many philosophies around implementation of lean and many opinions surrounding this concept as well. but i have found the most benefit by following Mr. Imai’s vision…

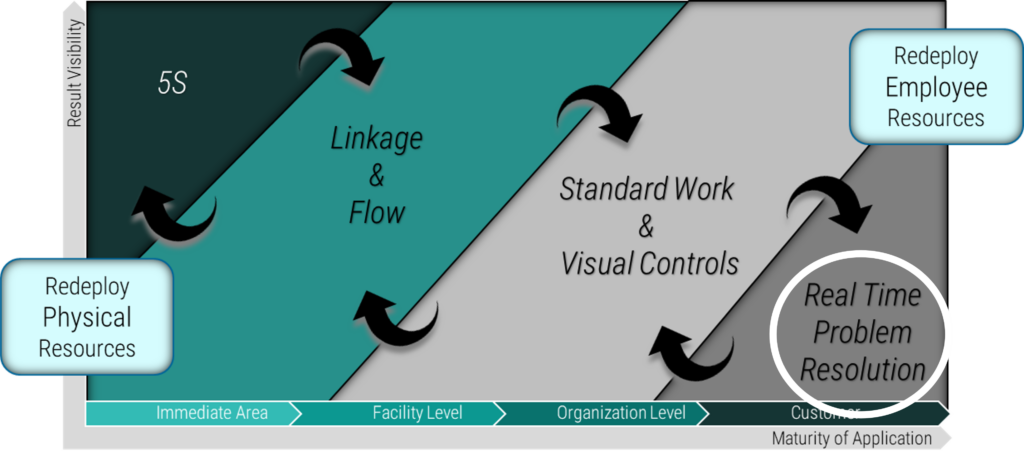

The cover picture for the next 5 months will be the stages in the imai process with a circle around the tool we will be going into a little more detail about during the month. (As we progress each month, I will highlight the stage as I did below with the current month’s topic.) The Imai process progresses in the following stages:

- 5S

- Linkage & Flow

- Standard Work

- Visual Controls (often times stages 3 & 4 are done at the same time)

- Real Time Problem Resolution

This month we discussed Real Time Problem Resolution (RTPR) and how it is the process that sustains continuous improvement. “What problem are you trying to solve?” is a common phrase I ask all the teams I have worked with or am currently working with. You may be asking yourself, “why? What’s in it for me (WIIFM)? Isn’t this just about supporting the bottom line? The problem doesn’t really effect me….right?”

The WHY: Real Time Problem Resolution is the process by which tools like Visual Controls and Standard Work are reviewed, monitored, and sustained. Yes, this does impact the bottom line and profitability…but it is still all about changing the way we think about our processes and procedures. The PROCESS, not the employee, is to be measured with the intent to understand process; rather than condemn or blame the employee. RTPR is how the team responds to the communication from the Visuals/Visual Controls and how they SEE the way that the business wants processes to interact. It’s the act of getting “life back to the good when things have gone bad”. It’s the response to the the red metrics, andon lights, or other indicators telling us something is wrong with the process and we need to address it…Not ignore or avoid it.

The WIIFM: I believe we as humans crave order and structure. When our lives or relationships are in chaos, we do not function well. This is why people visit Therapists, to have some form of normalcy (or structure) added back to their lives. Like children need boundaries to thrive in their development, adults need it too. Real Time Problem Resolution (RTPR) sustains that structure and order by responding to, not avoiding, problems. Hopefully resulting in a more productive and efficient process yes; but also giving formal structure to the work or tasks being performed. If done well, employees can visually see how processes impact structure and what wastes are impeding Continuous Improvement. RTPR in a simple form can always be tested and implemented, as the team progresses in understanding, the definition of RTPR will change and adapt as well. If RTPR is functioning well, the Culture has achieved what it needs to for operational excellence to thrive.

Again my word of caution: If the Culture of the organization is ready to implement a Continuous Improvement Journey, it will have embraced the concept of 5S First. If the Culture is not ready, they will fight it, avoid it, and sometimes badmouth it. If you find the team is badmouthing the 5S program, it would be wise to take a step back and see how the 5S program was rolled out or is evaluated. I have found that the more bureaucratized the process of evaluating the 5Ses, the more resistant the team is. We at Leanbrella would recommend that changes should be made to return to the concepts of the WHY and the WIIFM behind doing 5S before trying a more difficult concept like Linkage & Flow, Standard Work, or Visual Controls.

Real Time Problem Resolution (RTPR) is not limited to the workplace. It can be utilized in our personal lives as well. We face a series of problems every day…Disruptions in our daily expected routine, family or friend troubles, relationship issues, etc, etc, etc. Any attempt to take back control and try to resolve these problems is RTPR! Even recognizing the issue as an actual problem that needs resolution is progress. Keep it up!

So…”What problems are yOU trying to solve?”

If you need help understanding the problems you are facing, don’t hesitate to reach out to Leanbrella for support! I have had the opportunity and privilege to identify complex issues in a variety of situations and support teams and individuals overcome those issues. If you embark on a Continuous Improvement journey and start to realize that there are more problems than you can handle, you’re not alone! Start small and keep going. Two steps forward and one step back is sTILL progress! For the bigger stuff you cannot handle, Leanbrella can help…